Repairability of our products ensures longer life cycles

After long and intensive use, plus the wear and tear on the wear layers that goes with it, many of our products are easily repairable, giving them a much longer life cycle. A good example of this is our REGUPOL running track surfaces, which have been installed in athletics stadia across the globe. They are very sustainable, because if a track needs renovating after years of wear and tear, we can offer the option of a so-called “facelift.” To carry out such a facelift, only the partially or completely worn out sections of the track’s wear layer are ground off and repaired. The underlying REGUPOL elastic layer, essential for the entire system, remains in place in its original state. The entire track surface is then cleaned thoroughly and provided with a new, seamless REGUPOL PUR top surface. The base layers of our REGUPOL running tracks display almost the same sports-relevant physical properties and characteristics as when they were first installed, even after decades in use. This way, the track is given a “good-as-new” appearance and continues to meet all force reduction and other such demands. REGUPOL can apply this “face-lifting”, also known as “retopping”, to the old and worn tracks of most other manufacturers, as well.

For many operators, it’s very important that running track surfaces can be repaired rather than having to be completely renewed. This significantly reduces the costs for our customers and their sustainable action means environmental aspects are also taken into account.

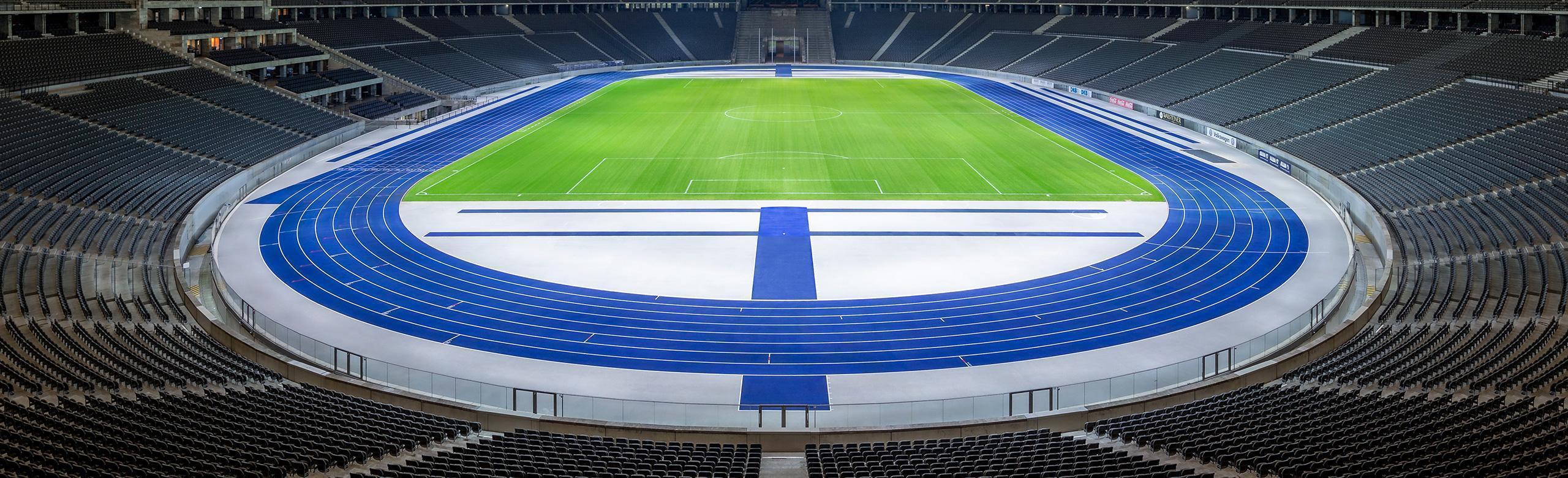

Since the 2009 World Championships, the blue running track in Berlin’s Olympic stadium has quite simply been the symbol of athletics in Germany. During the complete renovation of the stadium complex in 2004, a total of 9,100 m² of REGUPOL running track were installed in the stadium by our fitters.

At the World Athletics Championships in 2009, Usain Bolt set his as yet untouched world records over 100 and 200 m. Years later, the REGUPOL athletics surfaces underwent special treatment in the weeks and months before the 2018 European Championships. As we have the option of “re-topping” our running tracks, without significantly altering their properties and characteristics, replacing the synthetic surface completely wasn’t necessary. The track at the Olympic Stadium in Berlin was simply given a new wear layer. This process improves the heavily worn sections, provides the surface with a like-new appearance and, at the same time, is the most environmental solution.

In addition, a mobile sprint track was laid in the warm-up area inside the stadium, which, was also used for other events once the European Championships were over.

We try to give all our products the longest possible life cycle – because our environment and the economical use of resources are matters very close to our heart.

"REGUPOL offers one of the most sustainable running tracks there is, because it can be renewed so easily without having to tear everything up. They just take off the surface layer and re-top it. That’s not just easy on the finances of clubs and local authorities, but on the environment, too." - Thomas Eickmann, LAZ Puma